Indian Institute of Technology Madras researchers have developed a nano-coated filter media for healthcare workers treating COVID-19 Patients. This filter has applications not only in healthcare but also has defence applications and other places where air filtration of submicron particles is required

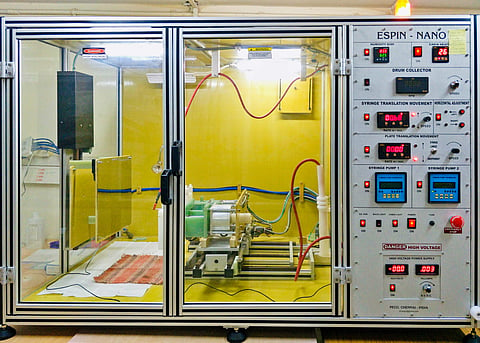

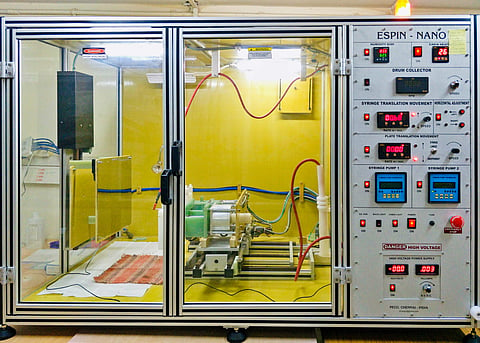

This nano-coated filter media has been fabricated by a nylon-based polymer coating on cellulose paper and was developed through the electrospinning process. The coating properties are optimised for efficient removal of sub-micron sized dust particles in the air.

The nano-coated filter media is in the process of being field-tested in practical applications. Upon validation through field trials, it will be recommended for bulk manufacturing through industry collaborations.

This work is funded by the Defence Research Development Organisation (DRDO) for defence applications and due to its high potential for the need of the hour, it is repositioned in health care applications.

Dr K Arul Prakash, Department of Applied Mechanics, IIT Madras, said, “The nano-coating fabricated through the electrospinning process have fibre diameter less than 1 micron and can be positioned according to the need to enhance surface/depth filtration for healthcare workers or public responders. This novel filter with multiple nano-coating have capabilities to filter particles of the order of one-micron size, which is a remarkable achievement.”

This project was a collaborative effort with faculty from various departments of IIT Madras including Dr Raghuram Chetty from Department of Chemical Engineering and Dr Saravana Kumar from the Department of Engineering Design.

Further, speaking about the applications in Defence, Dr K Arul Prakash added, “Nano-coated filter media have much better reverse cleanability behaviour resulting in an extended service life period of air filters providing prolonged working hours for armoured vehicles. This will save a huge cost for defence applications where the filters are currently imported from developed countries.”

The current status of the project is that the researchers are trying to optimise the coating parameters of nanomaterials for bulk manufacturing at an affordable cost and testing the antiviral properties for broader utilisation in various applications. Also, attempts are being made to develop composite nano-coated filter media having more than one nanomaterial coating with the possibility of manufacturing multi-layered masks.

Various characteristics of the nano-coated material such as permeability (a measure of flow-through media), coating thickness, and mechanical strength have been measured. The optimised nano-coated filter media has been developed using computer tools and validated with experimental results.

An increased filtration efficiency for submicron size dust particles of the order of 0.25 microns with a marginal increase in pressure drop is a notable achievement through this technology. The filtration can be further improved with multilayer nanomaterial coating. The nano-coated filter will not only be restricted for health care and defence applications but, in other places where air filtration of submicron particles is required. The computer simulation methodology adopted for the creation of the structure of the nanocoated filter media is also a novel development in this work.