Roti, kapda aur makaan — nutritious food, dignified clothes and a roof over our heads that we can call our own — this is the quintessential dream of every Indian, the bare necessities of life in fact. While most people are able to put food on the table three times a day and acquire adequate clothes to lead the supposed 'good life', the dream of that elusive home, one that we can truly call our own, remains unrealised for many. Real estate, huge interests, property tax — blame it on what you may, but two important factors are just how expensive and time-consuming it is to build a house. But if all goes well for Favo Construction Technologies (FCT), you will soon be able to check that box too.

The common thread that ran between the founders, Shiva Bhisne, Siri Chandana Vodela and Gaayatri Yaarlagadd, even before they ideated the start-up was Mahindra École Centrale (MEC), Hyderabad, where they studied, met and became friends. While Chandana and Gaayatri were mulling over an eco-friendly construction project, Shiva, their senior by a year, was working on a robotics project. When the three became friends, they joined forces and came up with the idea of FCT, a robotics and construction materials start-up. With FCT's 3D printing technology, it would be possible to 3D print multi-storied buildings layer by layer. They filed two patents for this technology and launched the start-up in 2018. By this year, they aim to execute their first project in Basar, Telangana — 10 units of 30 sqm cottages complete with a 300-metre compound wall.

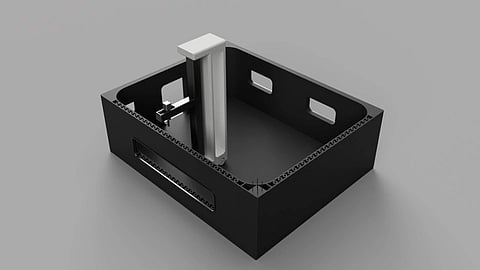

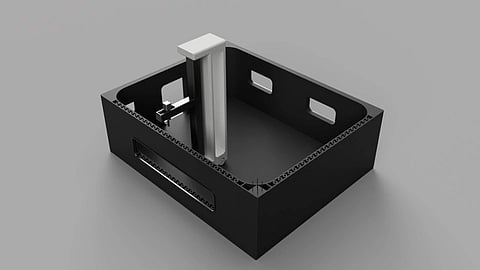

"Basically, once the foundation is set, the robotic arm is placed on the surface, PPC cement mixture is fed into the pipeline system, then the 3D printing begins," explains Chandana, who along with Gaayatri, pursued Civil Engineering while Shiva pursued Mechanical Engineering. The 3D printer prints the walls and the pillars. This construction method will help reduce the cost by 50 per cent and time by 60 per cent when compared to the traditional construction system, thus, making the dream of owning a house one day seem achievable. "That was our goal, people all over the world dream of owning a house, but never realise it. We wanted to make it a possibility," says the 22-year-old.

The 3D printer itself is equipped with a scanner for mapping and localisation to understand the environment. The architectural plan of the house is fed into their software which, in turn, develops a code that the 3D printer is able to understand. Then, the printing begins. Currently, they are in the prototyping stage and they very well realise that it may take a few years to mainstream this technology but they want to be ready with their solution and introduce it to the world as soon as possible.

On a related but unrelated note

According to a report by PropTiger, a real estate portal:

- Housing prices are up by 9 per cent in nine cities

- Hyderabad saw a maximum increase of 9 per cent in basic selling price

- Bengaluru and Kolkata witnessed a 3 per cent increase